Over the last few decades, robotic technology has advanced in leaps and bounds. Today, robots are used to assist in different businesses and manufacturing industries. The use of these robots boost profitability and productivity in any sector they are deployed. Compared to the benefit they bring, integrating robots into a business comes at a relatively affordable rate.

Collaborative robots are the newest types of robots to be introduced in the market. Unlike traditional robots, collaborative robots can work alongside humans to make work easier. They are easy to deploy and program without having to replace human employees.

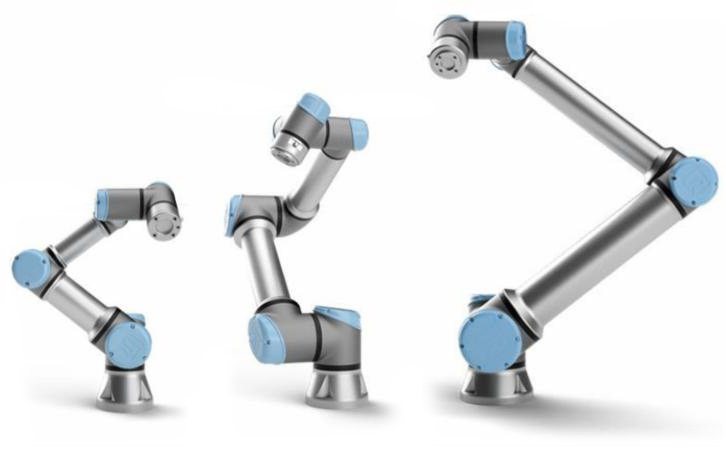

Universal collaborative robots

Universal Robots is a Danish robot manufacturing company that is at the forefront of robotics technology. To date, the company has sold more than 37000 collaborative robots to thousands of production and manufacturing plants around the world. This company manufactures small, flexible 6-axis robotic arms known as cobots. These cobots offer the user numerous benefits and features that significantly improve the profit margins of any company.

Here are unique reasons for any company to invest in universal robots.

They are easy to program

While there are numerous manufacturers of collaborative robots, ease of programming is one of the unique factors that set apart universal robots. The manufactures understand that not every manufacturing plant or company can afford an in-house programming department. For this reason, they create these universal robotic arms with easy to program features that can be handled by anyone, regardless of their programming expertise.

The programming sequence comprises of easy to follow instructions that help to move the robotic arm and set it up to perform desired tasks. The robots come with easy to use tablet software that uses arrow keys to move and point the arm as desired. A complete programming task takes not more than an hour.

Once it is programmed, the robotic arm works with speed and consistency to complete the tasks assigned. Unlike humans, the universal robot does not suffer from fatigue or boredom from doing repetitive tasks. It also does not need to take breaks or leave at the end of a shift. The ability to work round the clock, day in day out, makes these cobots reliable, time-efficient, and highly productive.

Universal Collaborative robs are safe

The advanced safety features built into universal collaborative robots makes them safe to work alongside humans. With traditional robots, manufacturing plants and companies have to create a caged environment for the robot work and keep humans out for safety purposes. Universal roots are called collaborative because they are built with the ability to work alongside human workers.

These safety features comprise of an in-built force sensor technology and 3D intuitive visualization. These are patented features that make the universal cobots aware of their environment. This gives them the ability to come to an instant halt whenever they sense the presence of human workers in their path. More than 80% of all sold universal robots work without the need of safety guarding after risk assessments.

These advanced safety features make it possible for manufacturing plants to deploy cobots to perform tasks that pose high humans injury risk. Employees are freed from these dangerous tasks to focus on more meaningful tasks in the company.

Universal collaborative robots can be used for anything

With a universal robot, there are numerous opportunities to automate repetitive tasks. You can use cobots to run press brakes, load machines, weld steel, stack finished parts, and sort materials, among many other tasks.

You can also use them for simple tasks like pick and place jobs or more intricately programmed tasks. Whichever task you program the arm for, you can be sure that it will be undertaken with uniform precision and speed.

Universal robots offer several different robotic arm models, numerous end-factors, and accessories. The UR3 is the smallest model and is best suited for small projects. There is the UR5 model with the ability to optimize processes like pick-and-place and testing. The UR10 is a much larger cobot designed for big tasks that require reliability and precision.